Electrostatic spraying represents one of the most efficient and innovative coating application methods in modern industrial processes. This advanced technology harnesses the power of electrical charges to achieve superior paint transfer rates, reduced waste, and exceptional surface coverage quality. Understanding the fundamental principles behind electrostatic spraying enables manufacturers, coating professionals, and industrial engineers to optimize their finishing operations while achieving consistent, high-quality results across diverse applications.

Fundamental Physics of Electrostatic Spraying

Electrical Charge Generation and Application

The core mechanism of electrostatic spraying relies on creating an electrical potential difference between the coating material and the target substrate. High-voltage generators, typically producing between 60,000 to 100,000 volts, charge the paint particles as they exit the spray gun or applicator. This electrical charging process transforms ordinary paint droplets into highly attracted particles that seek the nearest grounded surface with remarkable precision and efficiency.

During the charging phase, electrons are either added to or removed from the paint particles, creating a strong negative or positive charge. The substrate being coated is grounded, creating an opposite electrical potential that generates powerful attractive forces. These forces overcome gravity and air resistance, ensuring that charged paint particles follow curved trajectories toward the target surface rather than following straight paths dictated by spray momentum alone.

Coulomb's Law and Attraction Dynamics

The attractive forces governing electrostatic spraying operations follow Coulomb's Law, which states that the force between charged objects is directly proportional to the product of their charges and inversely proportional to the square of the distance between them. This fundamental principle explains why electrostatic spraying achieves superior wrap-around coverage compared to conventional spray methods, particularly on complex geometries and recessed areas.

As charged paint particles approach the grounded substrate, the electrical field strength increases exponentially, accelerating the particles toward the surface. This phenomenon creates the distinctive wraparound effect characteristic of electrostatic spraying, where paint particles curve around edges and penetrate into cavities that would remain poorly coated using traditional spray techniques.

Equipment Components and System Architecture

High Voltage Power Supply Systems

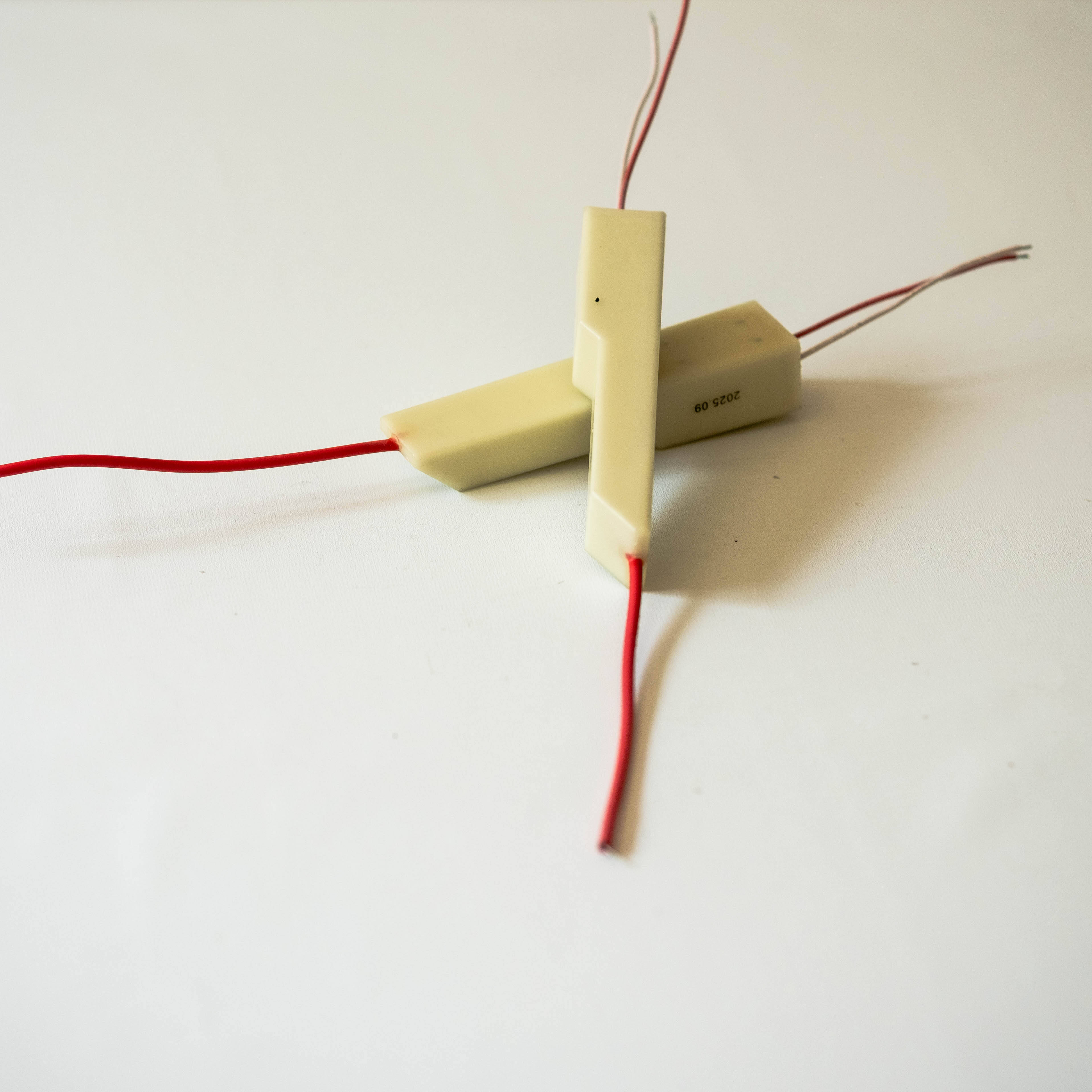

The heart of any electrostatic spraying system is the high-voltage power supply, which converts standard electrical input into the specialized high-voltage, low-current output required for effective particle charging. Modern power supplies incorporate sophisticated control circuits, safety systems, and monitoring capabilities to ensure consistent performance while protecting operators and equipment from electrical hazards.

Advanced electrostatic spraying systems feature variable voltage controls that allow operators to adjust charging levels based on coating material properties, substrate characteristics, and environmental conditions. These systems typically include automatic voltage regulation, arc detection circuits, and emergency shutdown mechanisms to maintain safe operation under varying conditions.

Spray Gun Design and Charging Mechanisms

Electrostatic spray guns incorporate specialized electrodes and charging systems designed to impart electrical charge to paint particles efficiently. Corona charging and contact charging represent the two primary methods employed in modern electrostatic spraying equipment. Corona charging uses a high-voltage electrode to create an electrical field that charges particles as they pass through the ionized air zone, while contact charging applies voltage directly to the paint material.

The design of spray gun components, including electrode geometry, air cap configuration, and fluid delivery systems, significantly impacts charging efficiency and spray pattern characteristics. Modern spray guns feature adjustable electrodes, replaceable charging rings, and precision-engineered air caps that optimize both particle charging and spray atomization for specific coating applications.

Material Properties and Coating Compatibility

Electrical Conductivity Requirements

Successful electrostatic spraying depends heavily on the electrical properties of both the coating material and the substrate. Coating materials must possess sufficient electrical conductivity to accept and retain electrical charge during the spraying process. Water-based coatings typically demonstrate excellent conductivity due to their ionic content, while solvent-based materials may require conductivity additives to achieve optimal electrostatic spraying performance.

Substrate conductivity plays an equally critical role in electrostatic spraying effectiveness. Conductive materials such as metals provide ideal grounding characteristics that maximize attractive forces and ensure uniform coating distribution. Non-conductive substrates like plastics or composites require special preparation techniques or conductive primers to enable effective electrostatic spraying applications.

Viscosity and Atomization Considerations

The viscosity of coating materials significantly influences both atomization quality and charging efficiency in electrostatic spraying systems. Lower viscosity materials generally atomize more readily and accept electrical charge more effectively, while higher viscosity coatings may require thinning or specialized application techniques to achieve optimal results.

Proper atomization is essential for effective electrostatic spraying because smaller particles have higher surface-area-to-mass ratios, enabling them to accept and retain electrical charge more efficiently. The relationship between viscosity, atomization pressure, and particle size distribution must be carefully balanced to maximize both transfer efficiency and coating quality in electrostatic spraying operations.

Process Variables and Optimization Strategies

Voltage and Current Control Parameters

Optimizing electrostatic spraying performance requires careful control of electrical parameters, including voltage levels, current limits, and charging duration. Higher voltages generally increase particle attraction and transfer efficiency but may also increase the risk of arcing, back-ionization, and safety hazards. Finding the optimal voltage range for specific applications involves balancing maximum transfer efficiency against operational safety and coating quality requirements.

Current monitoring provides valuable feedback about charging efficiency and system performance during electrostatic spraying operations. Excessive current levels may indicate problems with equipment condition, material conductivity, or environmental factors that could compromise coating quality or create safety risks.

Distance and Positioning Variables

The distance between the spray gun and target substrate critically affects electrostatic spraying performance through its influence on electrical field strength, particle trajectory, and transfer efficiency. Shorter distances increase field strength and particle attraction but may also increase arcing risks and reduce spray pattern uniformity. Longer distances provide better pattern distribution but may reduce transfer efficiency and increase overspray.

Optimal positioning strategies for electrostatic spraying consider substrate geometry, accessibility requirements, and desired coating thickness distribution. Complex parts may require multiple spray positions or specialized fixtures to ensure complete coverage while maintaining consistent electrostatic spraying effectiveness across all surfaces.

Transfer Efficiency and Environmental Benefits

Paint Utilization and Waste Reduction

Electrostatic spraying typically achieves transfer efficiencies between 85% and 95%, compared to 30% to 50% for conventional air spray methods. This dramatic improvement results from the electrical attraction forces that direct paint particles toward the target surface rather than allowing them to disperse into the surrounding environment as overspray waste.

The superior transfer efficiency of electrostatic spraying translates directly into reduced material consumption, lower coating costs, and decreased environmental impact through reduced volatile organic compound emissions. These benefits become particularly significant in high-volume production environments where even small efficiency improvements generate substantial cost savings and environmental advantages.

Air Quality and Emission Control

Reduced overspray generation from electrostatic spraying operations significantly improves air quality in finishing facilities and reduces the burden on ventilation and exhaust systems. Lower airborne particulate levels create safer working conditions for operators while reducing maintenance requirements for filtration equipment and exhaust systems.

The environmental benefits of electrostatic spraying extend beyond the immediate application area to include reduced waste disposal requirements, lower solvent consumption, and decreased energy consumption for ventilation systems. These advantages make electrostatic spraying an attractive option for companies seeking to improve their environmental performance while maintaining high coating quality standards.

Applications Across Industries

Automotive and Transportation Sectors

The automotive industry has embraced electrostatic spraying technology for both original equipment manufacturing and refinishing applications. Automotive paint lines utilize sophisticated electrostatic spraying systems to achieve the uniform, high-quality finishes demanded by modern vehicle aesthetics while maintaining the efficiency required for high-volume production.

Transportation equipment manufacturers, including manufacturers of trucks, buses, agricultural machinery, and construction equipment, rely on electrostatic spraying to provide durable, protective coatings that withstand harsh operating environments. The superior coverage characteristics of electrostatic spraying make it particularly valuable for coating complex vehicle components and assemblies.

Metal Fabrication and Industrial Manufacturing

Metal fabrication facilities utilize electrostatic spraying for both functional and decorative coating applications on a wide range of products including appliances, furniture, architectural components, and industrial equipment. The wraparound coverage capabilities of electrostatic spraying make it ideal for coating tubular structures, wire products, and complex assemblies that would be difficult to coat uniformly using conventional methods.

Industrial manufacturers appreciate the consistency and repeatability of electrostatic spraying processes, which help ensure uniform product quality and reduce rejection rates. The ability to achieve complete coverage with minimal material waste makes electrostatic spraying particularly attractive for high-value products where coating quality directly affects performance and longevity.

Safety Considerations and Best Practices

Electrical Safety Protocols

Safe operation of electrostatic spraying equipment requires comprehensive understanding of electrical hazards and implementation of appropriate safety protocols. High-voltage systems demand respect and careful attention to proper grounding, isolation procedures, and emergency shutdown capabilities. Operators must receive thorough training in electrical safety principles and equipment-specific procedures before working with electrostatic spraying systems.

Proper grounding of all system components, including spray booths, conveyors, and workpieces, is essential for both safety and performance in electrostatic spraying operations. Regular testing and maintenance of grounding systems ensures continued effectiveness and helps prevent dangerous electrical potentials from developing during operation.

Fire and Explosion Prevention

Electrostatic spraying operations using flammable materials require special attention to fire and explosion prevention measures. The combination of electrical energy and volatile solvents creates potential ignition sources that must be carefully controlled through proper ventilation, static electricity dissipation, and elimination of spark-producing equipment from hazardous areas.

Modern electrostatic spraying systems incorporate multiple safety features designed to minimize fire and explosion risks, including automatic shutdown systems, spark detection circuits, and intrinsically safe electrical designs. Regular maintenance and inspection of these safety systems ensures continued protection for personnel and facilities.

Troubleshooting Common Issues

Charging Problems and Solutions

Poor charging performance in electrostatic spraying systems can result from various factors including inadequate material conductivity, contaminated electrodes, or improper voltage settings. Systematic troubleshooting approaches help identify and resolve charging issues quickly to minimize production disruptions and maintain coating quality standards.

Regular cleaning and maintenance of charging electrodes prevents contamination buildup that can reduce charging efficiency and create arcing problems. Proper electrode positioning and replacement intervals ensure consistent electrostatic spraying performance over extended operating periods.

Coverage and Quality Issues

Uneven coverage or poor coating quality in electrostatic spraying applications often traces to improper system setup, environmental conditions, or material preparation issues. Understanding the relationship between electrical parameters, environmental factors, and coating properties enables operators to diagnose and correct quality problems effectively.

Environmental factors such as humidity, temperature, and air movement can significantly affect electrostatic spraying performance by influencing particle charging, trajectory, and adhesion characteristics. Monitoring and controlling these variables helps maintain consistent coating quality across varying operating conditions.

FAQ

How does electrostatic spraying differ from conventional spray painting methods

Electrostatic spraying uses electrical charges to attract paint particles to grounded surfaces, achieving 85-95% transfer efficiency compared to 30-50% for conventional methods. The electrical attraction creates wraparound coverage and reduces overspray waste significantly. Conventional spray methods rely solely on mechanical atomization and air pressure, resulting in more material waste and less uniform coverage on complex shapes.

What types of materials work best with electrostatic spraying systems

Conductive materials like water-based paints and properly formulated solvent-based coatings work best with electrostatic spraying. The coating material must have adequate electrical conductivity to accept and hold electrical charge during application. Non-conductive materials can be used with conductivity additives or special charging techniques, but conductive substrates like metals provide optimal results.

What safety precautions are necessary when operating electrostatic spraying equipment

Key safety measures include proper grounding of all equipment and workpieces, maintaining safe distances from high-voltage components, using appropriate personal protective equipment, and ensuring adequate ventilation for flammable vapors. Operators must receive comprehensive training on electrical hazards, emergency procedures, and equipment-specific safety protocols. Regular inspection and maintenance of safety systems is essential for continued safe operation.

Can electrostatic spraying be used for all coating applications

While electrostatic spraying offers significant advantages for many applications, it may not be suitable for all coating situations. Non-conductive substrates, extremely low-conductivity materials, or applications requiring specific spray patterns may benefit from alternative methods. The decision depends on substrate material, coating properties, production requirements, and quality specifications for each specific application.

Table of Contents

- Fundamental Physics of Electrostatic Spraying

- Equipment Components and System Architecture

- Material Properties and Coating Compatibility

- Process Variables and Optimization Strategies

- Transfer Efficiency and Environmental Benefits

- Applications Across Industries

- Safety Considerations and Best Practices

- Troubleshooting Common Issues

- FAQ