Energy efficiency has become a critical concern for manufacturing facilities worldwide, with production costs and environmental regulations driving the need for optimized electrical systems. High voltage modules represent a transformative technology that significantly enhances energy performance across various industrial applications. These sophisticated electrical components deliver precise power control while minimizing energy waste, making them essential for modern production environments seeking to reduce operational costs and environmental impact.

The implementation of high voltage modules in production facilities has revolutionized how manufacturers approach energy management. Unlike traditional electrical systems that often operate at fixed parameters, these advanced modules provide dynamic voltage regulation that adapts to real-time production demands. This adaptive capability ensures that energy consumption remains optimized throughout varying operational cycles, from peak production periods to maintenance shutdowns.

Manufacturing engineers increasingly recognize that energy efficiency directly correlates with production profitability. High voltage modules address this connection by delivering consistent electrical performance while reducing power losses typically associated with conventional voltage conversion systems. The precision control offered by these modules eliminates energy spikes and fluctuations that contribute to unnecessary power consumption and equipment wear.

Understanding High Voltage Module Technology

Core Components and Design Principles

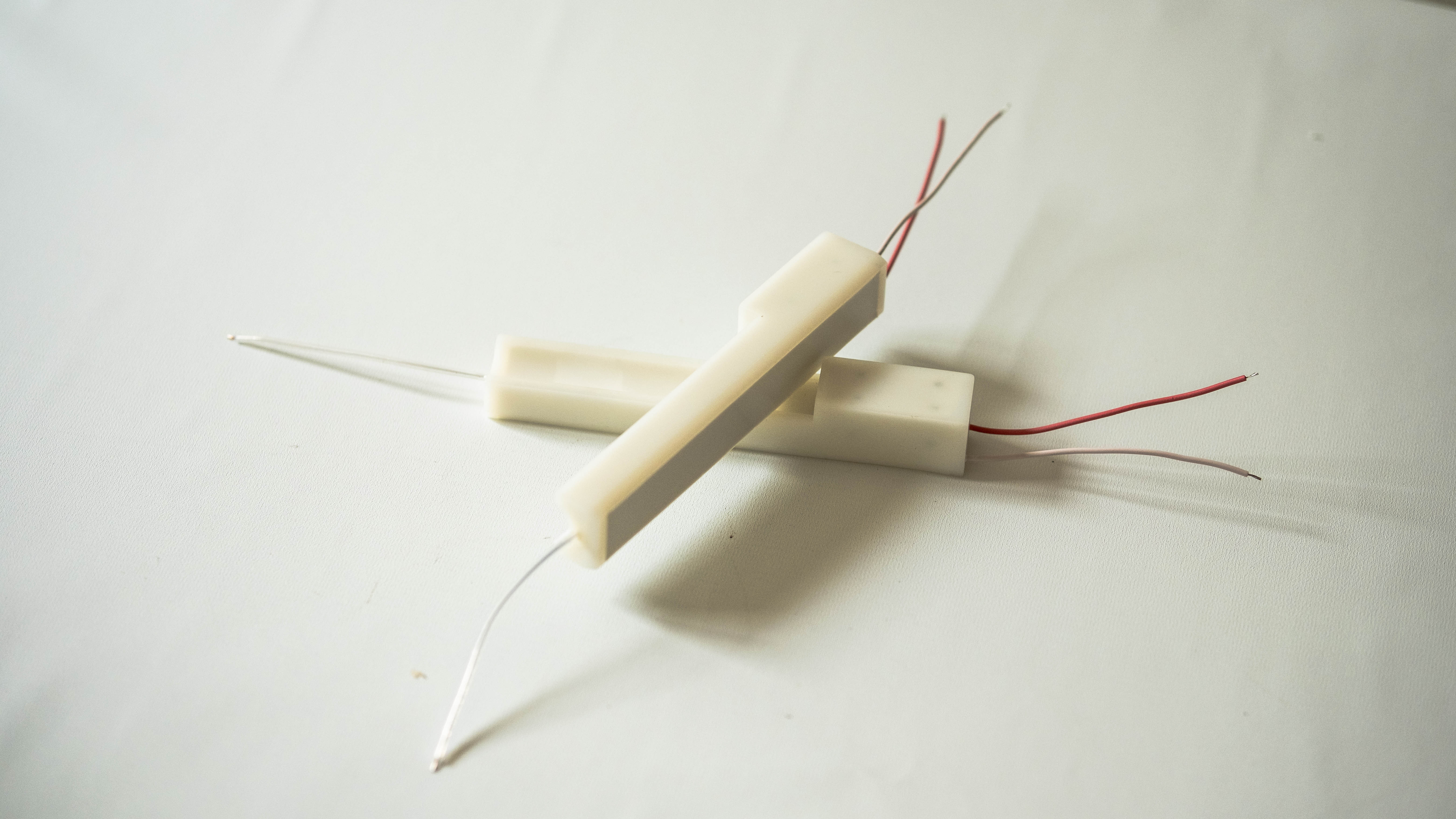

High voltage modules incorporate advanced semiconductor technology and sophisticated control circuits to achieve superior energy efficiency. The primary components include power transistors, transformers, capacitors, and intelligent control systems that work together to regulate voltage output with exceptional precision. These modules utilize switching technology that operates at high frequencies, reducing transformer size while improving overall efficiency compared to traditional linear systems.

The design principles behind high voltage modules focus on minimizing energy losses through optimized switching patterns and advanced thermal management. Modern modules employ silicon carbide and gallium nitride semiconductors that exhibit lower resistance and faster switching capabilities than conventional silicon-based components. This technological advancement enables high voltage modules to achieve efficiency ratings exceeding 95% in many applications.

Intelligent control systems within these modules continuously monitor input and output parameters, adjusting operation to maintain optimal efficiency regardless of load variations. This real-time adaptation prevents energy waste that occurs when electrical systems operate outside their optimal efficiency curves. The integration of digital signal processors and advanced algorithms enables predictive control that anticipates load changes before they occur.

Voltage Regulation Mechanisms

The voltage regulation capabilities of high voltage modules represent a significant advancement over traditional transformer-based systems. These modules employ pulse-width modulation and resonant switching techniques to maintain stable output voltages while minimizing switching losses. The precision of voltage regulation directly impacts energy efficiency by ensuring that connected equipment receives exactly the voltage required for optimal operation.

Advanced feedback control systems continuously measure output voltage and current, making microsecond-level adjustments to maintain stability. This rapid response capability prevents voltage droop and overshoot conditions that force connected equipment to operate inefficiently or activate internal compensation circuits. The result is consistent energy delivery that maximizes the efficiency of downstream production equipment.

High voltage modules also incorporate power factor correction technology that improves the overall efficiency of electrical systems. By maintaining near-unity power factor, these modules reduce reactive power consumption and minimize current requirements for a given power output. This improvement translates directly into reduced energy costs and improved system capacity utilization.

Energy Efficiency Benefits in Production Environments

Reduced Power Consumption

The implementation of high voltage modules in production facilities typically results in measurable reductions in overall power consumption. These savings stem from multiple factors, including improved conversion efficiency, reduced standby losses, and optimized power factor correction. Manufacturing facilities often report energy savings ranging from 15% to 30% when upgrading from conventional electrical systems to modern high voltage modules.

Power consumption reduction occurs through the elimination of energy losses associated with traditional voltage conversion methods. High voltage modules operate with conversion efficiencies that significantly exceed those of linear power supplies and older switching systems. The high-frequency switching technology employed in these modules reduces transformer core losses and improves overall system efficiency.

Standby power consumption represents another area where high voltage modules deliver significant improvements. Advanced sleep modes and intelligent power management features ensure that modules consume minimal energy during idle periods. This capability becomes particularly valuable in production environments with intermittent operations or varying production schedules.

Improved Equipment Performance

High voltage modules enhance the performance of connected production equipment by delivering clean, stable electrical power. The precision voltage regulation provided by these modules ensures that motors, drives, and other electrical equipment operate within their optimal efficiency ranges. This improved power quality extends equipment lifespan while maintaining peak performance characteristics.

The stable voltage output from high voltage modules reduces stress on electrical components within production equipment. Voltage fluctuations and harmonics common in traditional electrical systems cause additional heating and wear in motors and electronic components. By eliminating these power quality issues, high voltage modules contribute to reduced maintenance requirements and extended equipment service life.

Production equipment powered by high voltage modules often demonstrates improved precision and repeatability in manufacturing processes. The consistent electrical supply enables more accurate control of process parameters, resulting in higher product quality and reduced waste. This improvement in process control translates into both energy savings and improved production efficiency.

Implementation Strategies for Maximum Efficiency

System Integration Planning

Successful implementation of high voltage modules requires comprehensive planning that considers existing electrical infrastructure and production requirements. Engineers must evaluate current power distribution systems, identify inefficiency sources, and develop integration strategies that maximize the benefits of high voltage module technology. This planning phase involves detailed power audits and load analysis to determine optimal module specifications and placement.

The integration process benefits from a phased approach that allows for gradual system upgrades while maintaining production continuity. Priority should be given to high-energy consumption areas where high voltage modules can deliver the greatest efficiency improvements. This strategic implementation approach maximizes return on investment while minimizing operational disruption.

Compatibility assessment between existing equipment and proposed high voltage modules ensures seamless integration without unexpected performance issues. Modern high voltage modules offer various communication protocols and control interfaces that facilitate integration with existing automation systems and energy management platforms.

Optimization Techniques

Maximizing the efficiency benefits of high voltage modules requires ongoing optimization of operating parameters and system configuration. Regular monitoring of power consumption patterns, load factors, and efficiency metrics enables continuous improvement of system performance. Advanced monitoring systems provide real-time feedback that supports data-driven optimization decisions.

Load scheduling represents an important optimization strategy that leverages the adaptive capabilities of high voltage modules. By coordinating production schedules with optimal module operating conditions, facilities can achieve additional energy savings while maintaining production targets. This approach requires integration between production planning systems and electrical load management.

Preventive maintenance programs specifically designed for high voltage modules ensure sustained efficiency performance over time. Regular calibration of control systems, cleaning of heat dissipation components, and verification of electrical connections maintain optimal operating conditions. These maintenance practices prevent gradual efficiency degradation that can occur without proper attention to system upkeep.

Economic Impact and Cost Savings

Direct Energy Cost Reduction

The most immediate economic benefit of implementing high voltage modules comes from reduced electricity consumption and associated utility costs. Manufacturing facilities typically see significant reductions in monthly energy bills, with payback periods for module investments often ranging from 18 to 36 months depending on usage patterns and local utility rates. These savings compound over time, creating substantial long-term economic benefits.

Demand charge reductions represent another significant cost saving opportunity associated with high voltage modules. The improved power factor and reduced peak demand characteristics of these systems often result in lower utility demand charges. For industrial facilities with high peak power requirements, these demand charge savings can represent substantial monthly cost reductions.

Energy cost predictability improves when facilities implement high voltage modules due to their consistent efficiency characteristics. This predictability enables better budgeting and financial planning while reducing exposure to energy price volatility. The stable operating characteristics of high voltage modules provide confidence in long-term energy cost projections.

Operational Cost Benefits

Beyond direct energy savings, high voltage modules contribute to reduced operational costs through improved equipment reliability and extended service life. The clean power delivery characteristics of these modules reduce stress on connected equipment, resulting in lower maintenance requirements and fewer unexpected failures. This reliability improvement translates into reduced downtime costs and maintenance expenses.

Production efficiency improvements associated with high voltage modules create additional economic value through increased throughput and reduced waste. The stable power delivery enables more precise process control, resulting in higher quality products and reduced rework costs. These quality improvements often offset a significant portion of the initial investment in high voltage module technology.

Insurance and regulatory compliance costs may also decrease when facilities implement modern high voltage modules with advanced safety features and monitoring capabilities. These systems often exceed standard safety requirements and provide comprehensive operational data that supports regulatory reporting and risk management activities.

Future Trends and Technological Advances

Smart Grid Integration

The evolution of high voltage modules increasingly focuses on smart grid compatibility and bidirectional power flow capabilities. Future modules will incorporate advanced communication protocols that enable real-time interaction with utility grid systems, allowing facilities to participate in demand response programs and energy market activities. This integration creates additional revenue opportunities while optimizing overall energy efficiency.

Energy storage integration represents another frontier for high voltage module development. Advanced modules will incorporate seamless interfaces for battery systems and other energy storage technologies, enabling facilities to optimize energy usage patterns and reduce peak demand charges. This capability becomes particularly valuable as energy storage costs continue to decline.

Artificial intelligence and machine learning algorithms will enhance the adaptive capabilities of future high voltage modules. These intelligent systems will learn from historical usage patterns and predict optimal operating parameters for changing production conditions. The result will be autonomous optimization that continuously improves energy efficiency without requiring manual intervention.

Advanced Materials and Design

Ongoing developments in semiconductor materials promise even greater efficiency improvements for high voltage modules. Wide bandgap semiconductors such as silicon carbide and gallium nitride continue to advance, offering lower losses and higher operating temperatures. These materials enable more compact module designs with improved thermal performance and extended service life.

Magnetic component innovations including advanced core materials and winding techniques contribute to reduced losses and improved efficiency in high voltage modules. These improvements enable higher power density designs that require less installation space while delivering superior performance characteristics. The reduced size and weight of advanced modules simplifies installation and reduces infrastructure requirements.

Thermal management advances through improved cooling technologies and thermal interface materials enable high voltage modules to operate at higher efficiencies while maintaining reliable operation. Advanced cooling systems reduce operating temperatures, extending component life and enabling higher power density operation. These thermal improvements contribute directly to improved energy efficiency and system reliability.

FAQ

What is the typical efficiency improvement when implementing high voltage modules in production facilities

High voltage modules typically deliver efficiency improvements ranging from 15% to 30% compared to conventional electrical systems, depending on the specific application and existing infrastructure. These improvements result from reduced conversion losses, improved power factor correction, and optimized voltage regulation. The exact efficiency gain depends on factors such as load characteristics, operating patterns, and the condition of existing electrical equipment.

How long does it take to see return on investment from high voltage module implementation

Most manufacturing facilities experience payback periods between 18 and 36 months for high voltage module investments, with the exact timeframe depending on energy costs, usage patterns, and system complexity. Facilities with high energy consumption and variable load patterns typically achieve faster payback periods due to greater absolute savings. The return on investment calculation should include both direct energy savings and operational benefits such as reduced maintenance costs and improved equipment reliability.

Can high voltage modules be integrated with existing production equipment without major modifications

Modern high voltage modules are designed for compatibility with existing electrical systems and typically require minimal modifications for integration. Most modules include standard electrical interfaces and communication protocols that facilitate connection to existing equipment and control systems. However, proper engineering assessment is essential to ensure compatibility and optimize performance. Some older equipment may require minor modifications or interface devices to achieve full compatibility with advanced high voltage modules.

What maintenance requirements are associated with high voltage modules in production environments

High voltage modules require relatively minimal maintenance compared to traditional electrical systems, typically involving periodic inspection of electrical connections, cleaning of cooling components, and verification of control system calibration. Preventive maintenance schedules usually recommend quarterly visual inspections and annual comprehensive system checks. The solid-state design of modern high voltage modules eliminates many maintenance requirements associated with mechanical components, resulting in lower long-term maintenance costs and improved system reliability.

Table of Contents

- Understanding High Voltage Module Technology

- Energy Efficiency Benefits in Production Environments

- Implementation Strategies for Maximum Efficiency

- Economic Impact and Cost Savings

- Future Trends and Technological Advances

-

FAQ

- What is the typical efficiency improvement when implementing high voltage modules in production facilities

- How long does it take to see return on investment from high voltage module implementation

- Can high voltage modules be integrated with existing production equipment without major modifications

- What maintenance requirements are associated with high voltage modules in production environments