A flyback transformer represents one of the most crucial components in high voltage power conversion systems, serving as the backbone for countless electronic devices from CRT televisions to LED drivers and switching power supplies. This specialized transformer operates on fundamentally different principles compared to conventional transformers, utilizing energy storage and release cycles to achieve efficient voltage conversion and isolation. Understanding the intricate workings of a flyback transformer becomes essential for engineers and technicians working with high voltage applications, as these components directly impact system performance, efficiency, and safety considerations.

Fundamental Operating Principles of Flyback Transformers

Energy Storage Mechanism

The flyback transformer operates through a unique energy storage and transfer mechanism that distinguishes it from linear transformers. During the switch-on period, the primary winding of the flyback transformer stores magnetic energy in its core while the secondary windings remain electrically isolated. This energy accumulation phase is critical because it determines the transformer's power handling capacity and efficiency characteristics. The magnetic core material, typically ferrite for high-frequency applications, must possess specific permeability and saturation characteristics to handle the energy storage requirements effectively.

The energy storage process involves building up magnetic flux density within the core material as current flows through the primary winding. This stored energy represents the power that will subsequently be transferred to the secondary circuit during the switch-off period. The amount of energy stored depends on the inductance of the primary winding, the peak current reached, and the magnetic properties of the core material. Engineers must carefully calculate these parameters to ensure optimal performance and prevent core saturation, which could lead to transformer failure or inefficient operation.

Energy Transfer and Release Cycle

When the primary switch opens, the stored magnetic energy in the flyback transformer core begins transferring to the secondary windings through electromagnetic induction. This energy release phase generates high voltage spikes across the secondary windings, making flyback transformers particularly suitable for high voltage applications. The voltage magnitude depends on the turns ratio between primary and secondary windings, similar to conventional transformers, but the peak voltages can be significantly higher due to the energy storage mechanism.

The energy transfer efficiency of a flyback transformer depends heavily on timing control and load characteristics. Proper switching frequency selection ensures complete energy transfer from core to load before the next switching cycle begins. Incomplete energy transfer can lead to core heating, reduced efficiency, and potential component stress. The flyback transformer design must account for these timing considerations to maintain stable operation across varying load conditions and input voltage ranges.

High Voltage Generation Techniques

Voltage Multiplication Through Turns Ratio

High voltage generation in flyback transformer systems relies primarily on the turns ratio between primary and secondary windings, combined with the energy storage characteristics of the magnetic core. The voltage transformation ratio follows the same basic principles as conventional transformers, where the secondary voltage equals the primary voltage multiplied by the turns ratio. However, flyback transformers can achieve much higher instantaneous voltages due to the rapid energy release during the switch-off period, making them ideal for applications requiring kilovolt-level outputs from relatively low input voltages.

The winding configuration significantly affects the high voltage performance of a flyback transformer. Multiple secondary windings can be implemented to provide different output voltage levels or to achieve voltage doubling and multiplication effects. Each secondary winding must be carefully insulated and positioned to withstand the high voltage stresses while maintaining proper coupling with the primary winding. The insulation system typically includes multiple layers of specialized materials capable of withstanding both steady-state and transient voltage stresses.

Peak Voltage Control and Regulation

Controlling peak voltages in flyback transformer applications requires sophisticated switching control circuits that monitor both primary and secondary parameters. The peak voltage across the secondary windings occurs immediately after the primary switch opens, and this voltage level must be carefully controlled to prevent component damage while maintaining proper load regulation. Feedback control systems typically monitor the output voltage and adjust the primary switching duty cycle to maintain stable high voltage output despite variations in input voltage or load conditions.

Voltage regulation techniques for flyback transformer systems include pulse width modulation, frequency modulation, and hybrid control methods. Each approach offers specific advantages depending on the application requirements. PWM control provides excellent load regulation but may generate higher electromagnetic interference, while frequency modulation can reduce EMI at the expense of more complex filter requirements. The choice of regulation method directly impacts the overall system efficiency and performance characteristics.

Core Design and Material Selection

Magnetic Core Materials

The selection of appropriate core materials is fundamental to flyback transformer performance in high voltage systems. Ferrite cores are most commonly used due to their high permeability, low core losses at switching frequencies, and excellent temperature stability. The specific ferrite composition affects saturation flux density, permeability variations with temperature, and core loss characteristics. High-frequency flyback transformer applications typically utilize manganese-zinc ferrite cores, while lower frequency applications may use nickel-zinc ferrite materials.

Core geometry plays a crucial role in flyback transformer design optimization. E-core, ETD, and EFD core shapes are popular choices for flyback transformer applications due to their favorable winding windows and heat dissipation characteristics. The core cross-sectional area determines the maximum flux density and power handling capability, while the magnetic path length affects the magnetizing inductance and energy storage capacity. Proper core sizing ensures operation below saturation limits while maximizing energy storage efficiency.

Air Gap Implementation

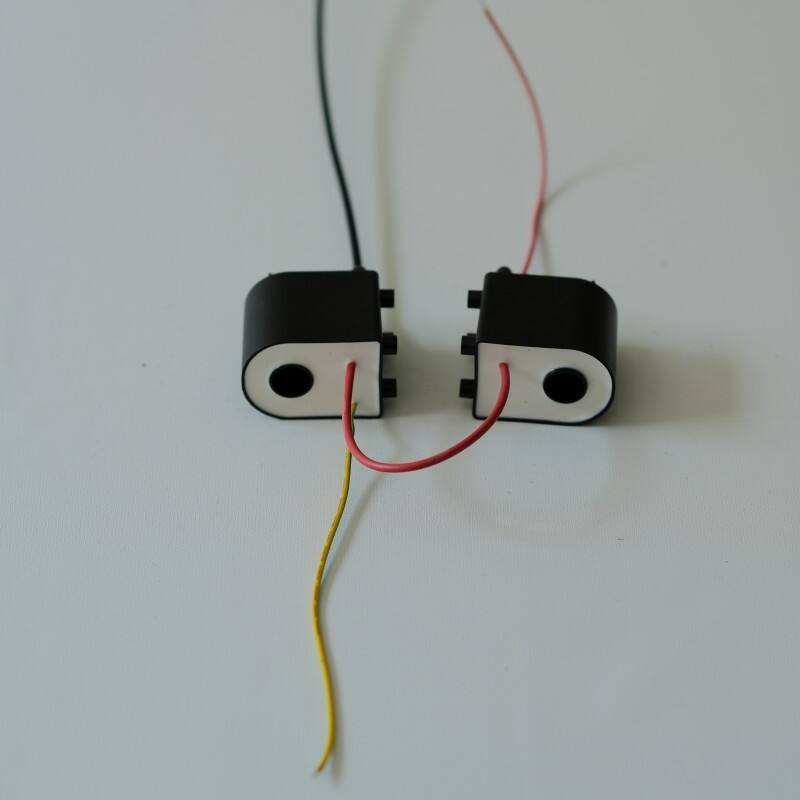

Most flyback transformer designs incorporate controlled air gaps in the magnetic core to prevent saturation and provide linear inductance characteristics. The air gap stores a significant portion of the magnetic energy and prevents the core from entering saturation during high current conditions. Gap length calculation requires careful consideration of the desired inductance value, maximum current levels, and core material properties. Distributed air gaps are often preferred over single gaps to reduce fringing field effects and electromagnetic interference.

Air gap implementation affects both electrical and mechanical characteristics of the flyback transformer. Mechanically, the gap must be precisely controlled and stable over temperature variations to maintain consistent electrical performance. Electrically, the gap introduces additional reluctance that reduces the overall permeability and affects the energy storage capability. The gap also influences the transformer's acoustic noise characteristics, as magnetostrictive forces can cause audible vibrations in the core structure.

Switching Control and Timing

Primary Side Control Circuits

Primary side control circuits for flyback transformer systems manage the switching timing and current flow through the primary winding. These circuits typically include a power MOSFET or IGBT as the main switching element, along with gate drive circuits that provide the necessary voltage and current to control the switch operation. The switching frequency selection impacts transformer size, efficiency, and electromagnetic interference characteristics. Higher frequencies allow smaller transformer cores but may increase switching losses and require more sophisticated control circuits.

Current sensing and protection circuits are essential components of flyback transformer control systems. Primary current sensing enables overcurrent protection and can provide feedback for output regulation in primary-side controlled systems. Various current sensing techniques include resistive sensing, current transformers, and Hall effect sensors, each offering different advantages in terms of accuracy, cost, and isolation requirements. The current sensing information feeds back to the control circuit to optimize switching timing and protect against fault conditions.

Timing Synchronization

Precise timing control is critical for efficient flyback transformer operation, as the energy transfer process depends on accurate synchronization between energy storage and release phases. The switch-on time determines how much energy is stored in the magnetic core, while the switch-off time allows for complete energy transfer to the secondary circuit. Improper timing can result in incomplete energy transfer, increased losses, and potential component stress. Advanced control circuits use adaptive timing algorithms that adjust switching parameters based on load conditions and input voltage variations.

Multi-output flyback transformer systems require additional timing considerations to ensure proper energy distribution among different output channels. Cross-regulation between outputs can be minimized through careful transformer design and control circuit optimization. Some applications use post-regulation circuits on individual outputs to maintain tight voltage regulation, while others rely on primary-side control with compensation for cross-regulation effects.

Isolation and Safety Considerations

Electrical Isolation Requirements

Flyback transformer systems provide excellent electrical isolation between primary and secondary circuits, making them suitable for applications requiring safety isolation or ground loop elimination. The isolation voltage capability depends on the transformer construction, including winding separation, insulation materials, and creepage distances. High voltage flyback transformer applications may require isolation ratings of several kilovolts, necessitating specialized insulation systems and construction techniques.

Safety standards such as UL, IEC, and EN specify minimum requirements for isolation voltage, creepage distances, and insulation coordination in flyback transformer designs. These standards consider both steady-state and transient voltage stresses, including lightning impulses and switching transients. Compliance with safety standards is essential for commercial products and requires careful attention to insulation design, material selection, and testing procedures.

Protection Circuit Integration

Comprehensive protection circuits are essential for safe flyback transformer operation in high voltage systems. Overvoltage protection prevents excessive voltage stress on secondary components and loads, while overcurrent protection guards against primary winding damage and core saturation. Thermal protection monitors transformer temperature and initiates shutdown if safe operating limits are exceeded. These protection functions can be implemented using discrete components or integrated into control IC solutions.

Fault detection and diagnostic capabilities enhance the reliability and maintainability of flyback transformer systems. Advanced protection circuits can detect various fault conditions including short circuits, open circuits, and degraded insulation. Some systems provide fault logging and communication interfaces for system-level monitoring and predictive maintenance. The integration of protection and diagnostic functions requires careful consideration of response times, false triggering prevention, and recovery procedures.

Applications in High Voltage Systems

Power Supply Applications

Flyback transformer technology finds extensive use in switched-mode power supplies for high voltage applications, including CRT displays, electrostatic precipitators, and scientific instrumentation. The inherent voltage regulation capabilities and compact size make flyback transformer designs attractive for applications requiring multiple output voltages with good isolation characteristics. The ability to generate high voltages from low input voltages reduces the complexity of input rectification and filtering circuits.

Modern flyback transformer power supplies incorporate sophisticated control techniques to improve efficiency and reduce electromagnetic interference. Quasi-resonant and resonant flyback topologies can achieve higher efficiency than conventional hard-switching designs by reducing switching losses and electromagnetic interference. These advanced topologies require careful design of resonant components and control circuits but offer significant performance improvements for high-power applications.

Specialized High Voltage Equipment

Industrial high voltage equipment utilizes flyback transformer technology in applications such as electrostatic painting systems, air purification devices, and X-ray equipment. These applications require precise voltage control, excellent regulation, and high reliability under demanding operating conditions. The flyback transformer design must accommodate specific requirements such as high altitude operation, temperature extremes, and electromagnetic interference limits.

Medical and scientific equipment applications place additional requirements on flyback transformer design, including patient safety isolation, low electromagnetic emissions, and high reliability standards. These applications often require custom transformer designs optimized for specific voltage, power, and environmental requirements. Quality control and testing procedures for medical applications typically exceed standard commercial requirements and may include additional verification of isolation integrity and electromagnetic compatibility.

FAQ

What makes flyback transformers different from regular transformers

Flyback transformers differ from regular transformers in their energy storage and transfer mechanism. While regular transformers transfer energy continuously through electromagnetic coupling, flyback transformers store energy in their magnetic core during the switch-on period and release it to the secondary circuit during the switch-off period. This fundamental difference allows flyback transformers to generate much higher voltage ratios and provide better isolation between primary and secondary circuits, making them ideal for high voltage applications and switched-mode power supplies.

How do you calculate the turns ratio for a flyback transformer

The turns ratio calculation for a flyback transformer follows the same basic principle as conventional transformers, where the voltage ratio equals the turns ratio. However, flyback transformer calculations must also consider the energy storage requirements, maximum duty cycle, and voltage stress limitations. The turns ratio is typically calculated as the desired output voltage divided by the input voltage, multiplied by a factor accounting for voltage drops and regulation requirements. Additional considerations include the maximum flux density in the core and the primary inductance required for proper energy storage.

What are the main safety concerns with high voltage flyback transformers

High voltage flyback transformers present several safety concerns that require careful attention during design and operation. The primary safety concern is the high voltage output that can cause electric shock or electrocution if proper precautions are not taken. Adequate insulation, proper grounding, and protective enclosures are essential safety measures. Additionally, flyback transformers can generate high voltage spikes and electromagnetic interference that may affect nearby electronic equipment. Proper shielding, filtering, and isolation techniques are necessary to ensure safe and compliant operation in accordance with relevant safety standards.

Why do flyback transformers need air gaps in their cores

Air gaps in flyback transformer cores serve multiple critical functions that are essential for proper operation. The primary purpose is to prevent core saturation by providing a controlled reluctance that limits the maximum flux density in the magnetic core material. The air gap also stores a significant portion of the magnetic energy, which is crucial for the flyback transformer's energy storage and transfer mechanism. Additionally, the air gap provides more linear inductance characteristics and helps maintain consistent performance across varying current levels. Without proper air gaps, the transformer core would saturate easily, leading to reduced efficiency, increased losses, and potential component failure.