100W High Voltage Transformer

| Place of Origin | China |

| Brand Name | Hanghangxing |

| Certification | CE |

- Overview

- Recommended Products

Description

Our high-voltage power module is engineered as the core component for modern kitchen fume purification systems. It is designed to deliver unmatched performance, safety, and reliability through a meticulous selection of materials and innovative engineering.

1. Superior Material Selection for Maximum Safety & Durability

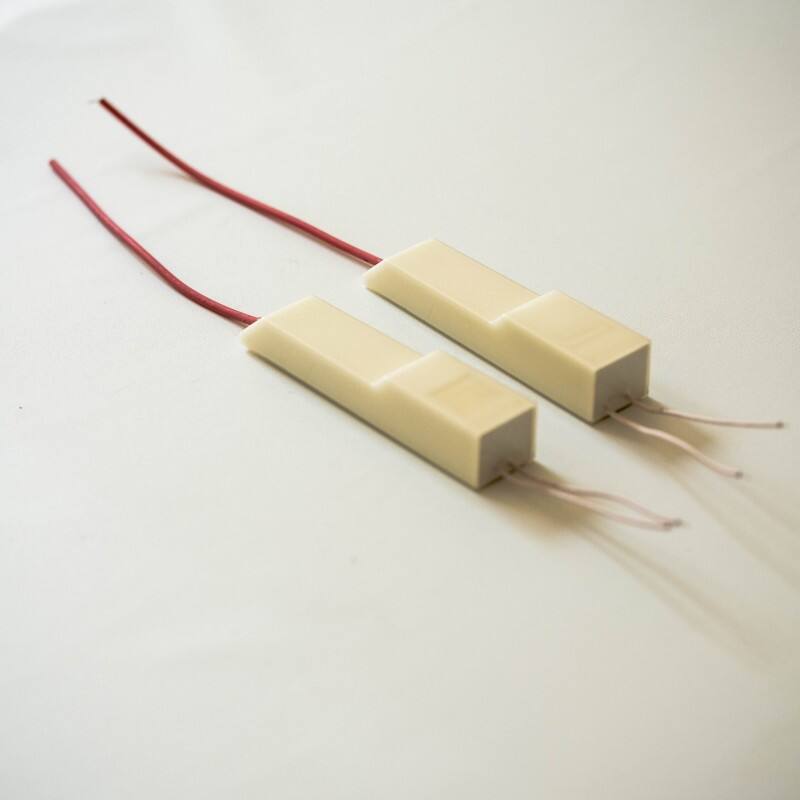

· Flame-Retardant PPO Housing: We insist on using Polyphenylene Oxide (PPO) for the product housing, a premium engineering plastic chosen for its exceptional properties. This commitment directly translates into enhanced high-temperature resistance and operational safety.

· Exceptional Electrical Insulation: PPO boasts one of the lowest dielectric constants and dissipation factors among all engineering plastics. Critically, these electrical properties remain stable across a wide range of temperatures and humidity levels, making it an ideal material for applications across low-, medium-, and high-frequency electric fields. This inherent stability ensures consistent insulation, a critical factor for high-voltage components.

· Outstanding Thermal Stability: With a heat deflection temperature exceeding 190°C and a brittle point as low as -170°C, PPO guarantees that our housing maintains its structural integrity and dimensional stability under extreme operating conditions. The use of PPO is a fundamental assurance of the product's long-term reliability, flame retardancy, and resistance to thermal deformation.

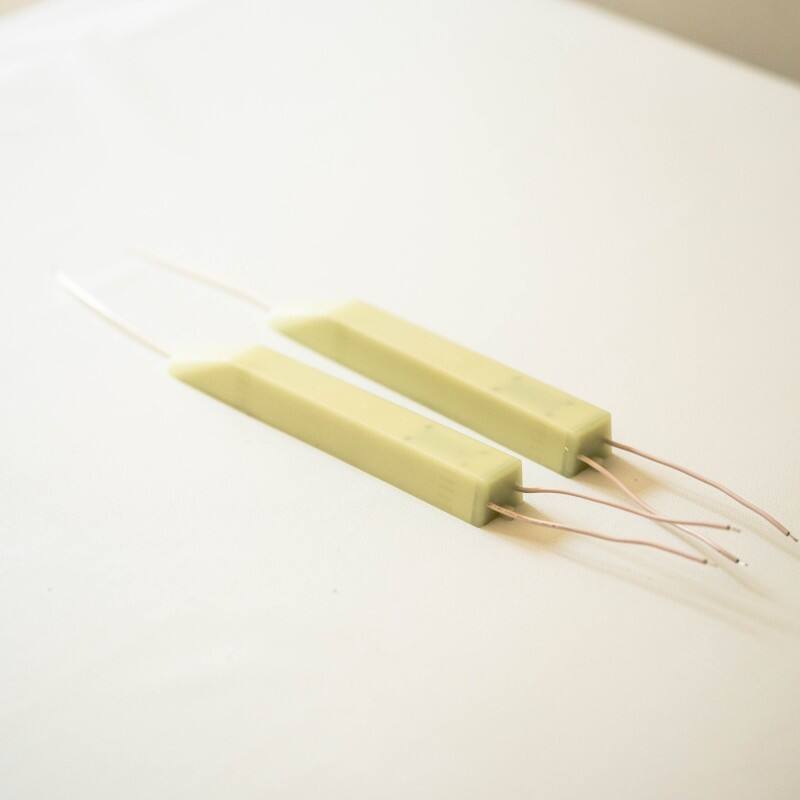

2. High-Voltage Cables with Exceptional Chemical Resistance

· Teflon Insulation: For the critical high-voltage cables, we utilize Teflon (PTFE). This material provides superior resistance to oil, strong acids, alkalis, and oxidants. Its non-hygroscopic nature (does not absorb moisture) is vital for preventing current leakage and tracking. This choice significantly boosts the overall insulation strength and high-voltage endurance of the module, ensuring stable performance in harsh kitchen environments.

3. User-Centric Design for Effortless Installation

· Revolutionized Mounting System: Moving beyond the messy and time-consuming tradition of adhesive fixation, we have developed a streamlined bolt-on mounting system via integrated fixing holes. This innovation simplifies installation for our clients, drastically reduces installation time, and completely eliminates the waiting period required for adhesive curing. This leads to faster commissioning and lower overall labor costs.

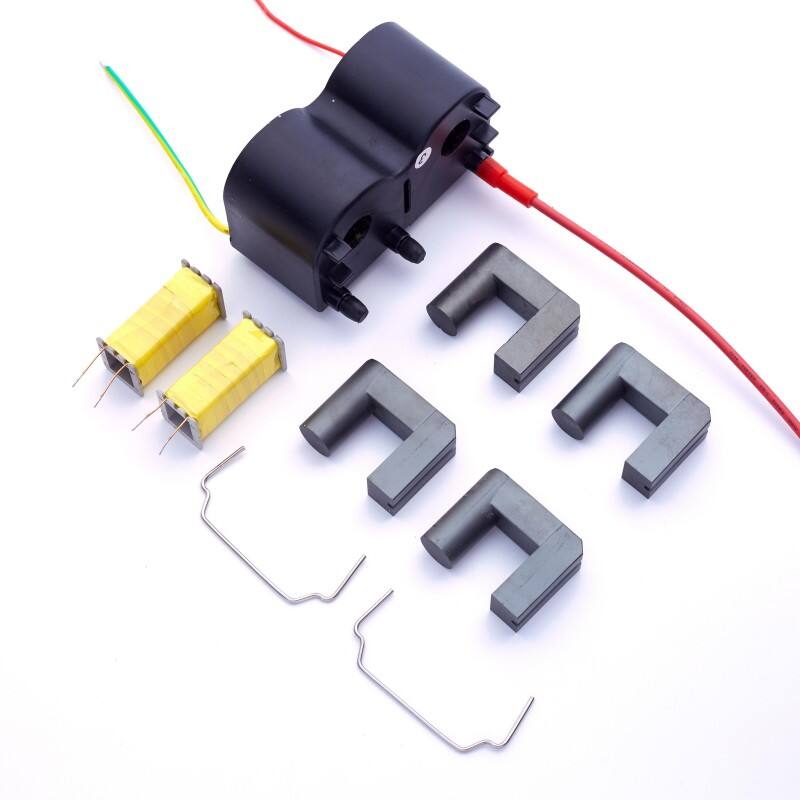

4. Structural Innovation for Enhanced Performance

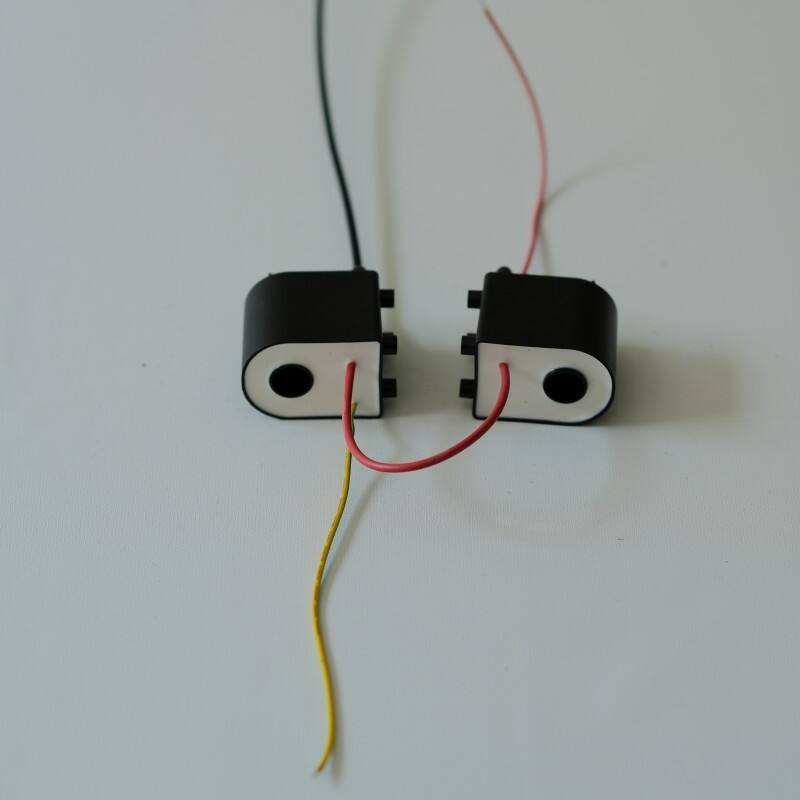

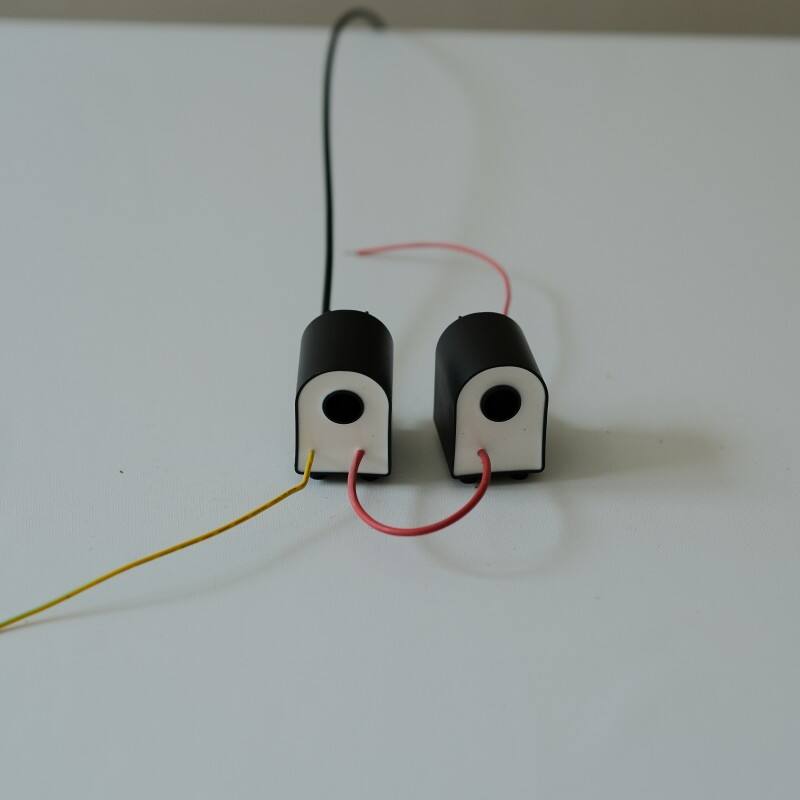

· Integrated Monobloc Design: Our groundbreaking integrated housing structure represents a significant leap forward. It is meticulously designed to provide superior protection and insulation at the high-voltage series connection points.

· Eliminates Arcing & Boosts Power: This robust design effectively mitigates the risk of arcing or sparking at these critical junctions. Furthermore, the compact and efficient layout not only reduces the overall footprint of the unit but also allows for an increase in the module's power output and operational voltage, delivering higher performance from a smaller package.

Specifications

| Place of Origin | China |

| Size of product | 92*64*47mm |

| Size of Epoxy Ferrite Core | 50*38mm |

| Weight | 775g |

| Output Power | 400W |

Applications

· Large-Scale Industrial Kitchens

· Mobile Food Vending Carts

In the oil fume purification systems of commercial kitchens, the core of purification effectiveness begins with a powerful "heart" – the high-voltage electrostatic power supply. The beat of this heart originates from its most precise and critical internal component: the High-Voltage Generator (HV Generator).

As a professional manufacturer of High-Voltage Generators, Yangzhou Sanxing Technology CO.,LTD understands that a stable and powerful HV Generator is the starting point of the entire purification chain. This article will provide an in-depth look at how our HV Generators work in synergy with the power supply system to ultimately achieve efficient adsorption and purification of oil fumes.

Step 1: Precision Installation – Laying the Foundation for the Electrostatic Field

Our HV Generators are designed from the ground up with compatibility and ease of installation in various power supply enclosures in mind.

1. Positioning and Fixing: The power supply enclosure has a dedicated mounting location for the HV Generator, typically secured using standard brackets or screw holes. Our HV Generators feature a compact structure and standardized interfaces, ensuring a secure fit and preventing connection loosening due to vibration.

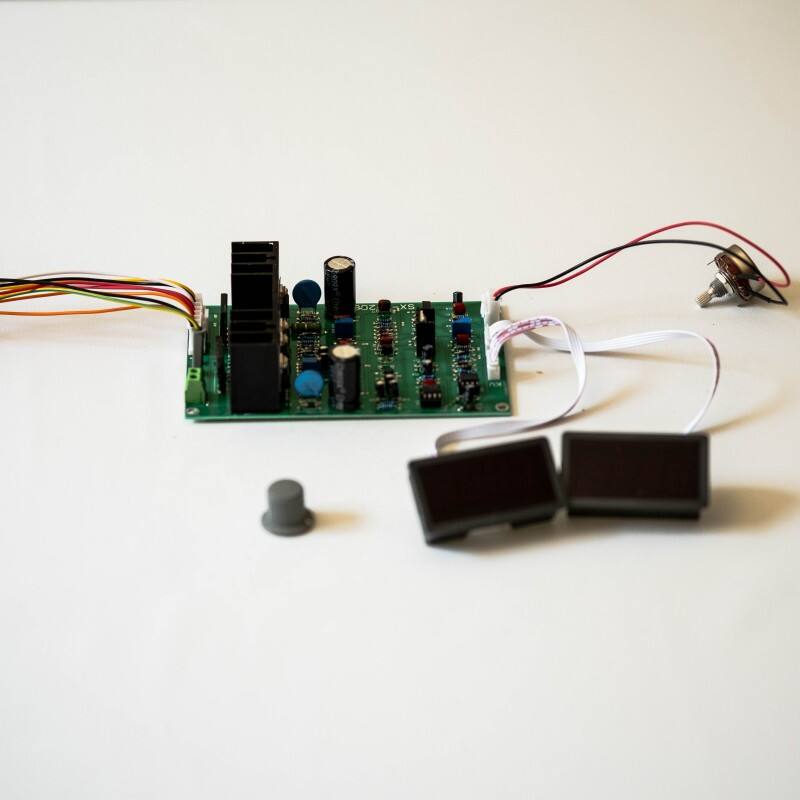

2. Electrical Connections:

· Input (Low-Voltage Side): Connects to the DC low-voltage power source (e.g., 12V/24V) and control signals from the power supply control board. Our products feature clear wiring markings and fool-proof connection designs, significantly reducing the risk of misconnection.

· Output (High-Voltage Side): Connects to the anode (e.g., ionization tubes, anode cylinders) of the purifier's electric field unit via specially designed high-voltage insulated cables. We use high-quality high-voltage silicone rubber wires, resistant to high voltage, high temperature, and flame, ensuring lossless and safe energy transmission.

3. Insulation and Protection:

Once installed, the entire HV Generator module is sealed within the power supply enclosure, isolated from the external environment. This provides not only dust and moisture protection but, crucially, ensures the safety of the high-voltage section, preventing any risk of leakage.

At this point, an "energy core" capable of providing tens of thousands of volts of ultra-high voltage to the purification electric field is ready.

Step 2: Synergistic Operation – Unleashing the Power of Electrostatic Adsorption

Once the power supply is energized, an efficient "fume hunt" commences:

1. Energy Conversion (The Mission of the HV Generator): The power supply control board converts mains electricity (220V AC) into stable low-voltage DC power, which is fed into the [Your Brand] High-Voltage Generator. Internally, our HV Generator uses high-frequency oscillation, a step-up transformer, and a voltage multiplier rectification circuit to instantly boost this low-voltage energy into a DC negative high voltage of 10,000V to 20,000V.

2. Electrostatic Field Formation (The Duty of the Electric Field Zone): This powerful negative high voltage is applied to the anodes in the purifier's electric field zone, creating an inhomogeneous high-voltage electrostatic field between them and the grounded cathodes (e.g., collector plates, enclosure).

3. The "Three-Axe" Purification Process:

· Ionization: As the oil-fume laden exhaust air passes through this powerful electrostatic field, the oil mist particles collide with high-speed electrons and are instantly charged with a negative charge.

· Adsorption: The negatively charged oil mist particles, driven by the electric field force (Coulomb force), are rapidly attracted to and firmly adsorbed onto the positively charged, grounded cathode plates, much like iron filings drawn to a magnet.

· Deposition and Collection: Over time, the captured oil droplets coalesce on the surface of the plates under the influence of gravity, eventually forming larger droplets that drain into the bottom collection tray, completing the "gas-to-liquid" separation of the oil fumes.

FAQ

Q:How long does production and delivery take?

A:The production cycle for standard parameters typically ranges from 4 to 5 days, while customized products may take up to 10 days. Generally, the logistics time for international shipments is between one and two weeks.

Q:Can I request custom designs or sizes?

A:Certainly. We can manufacture products according to the parameters you provide. Regarding the dimensions, we will definitely meet your requirements to the best of our ability. If the subsequent order volume is substantial, we can offer the service of creating a dedicated mold for your specified products at our own expense.

Q:What is the fastest way to contact you?

A:WeChat APP is the fastest way to contact me,my ID is ppxs0712,and you can also send me email,I will check it everyday. My phone number is +8618168269966,and my email is [email protected].

Q:What are your shipping terms?

A:Normally, the volume of our goods is not very large. For international shipments, we do not cover the shipping costs. Usually, the shipping fees are calculated based on the weight and volume of the products. According to our past experience, the shipping costs will not be very high.