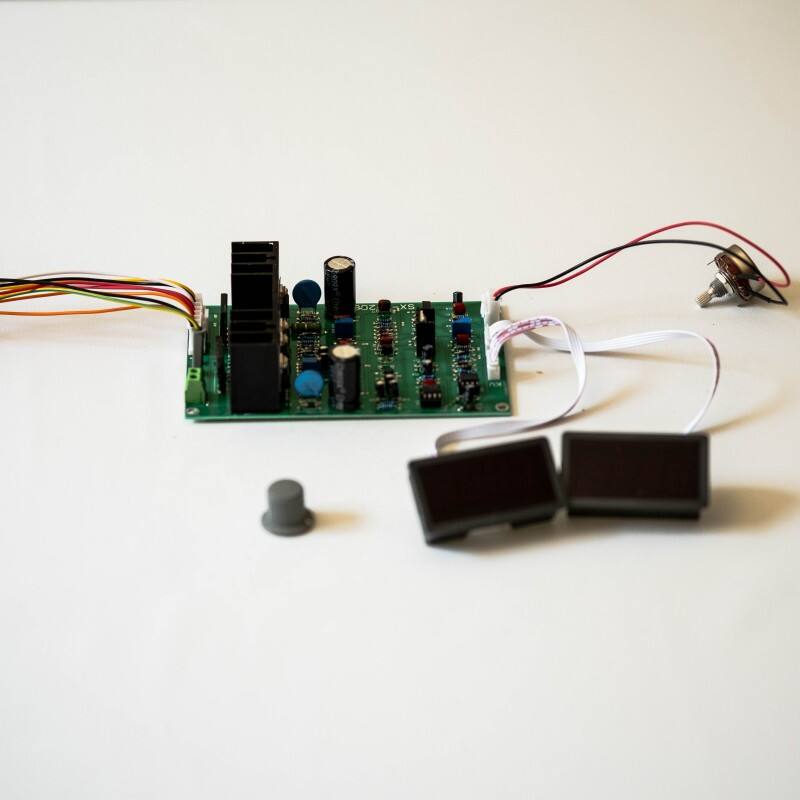

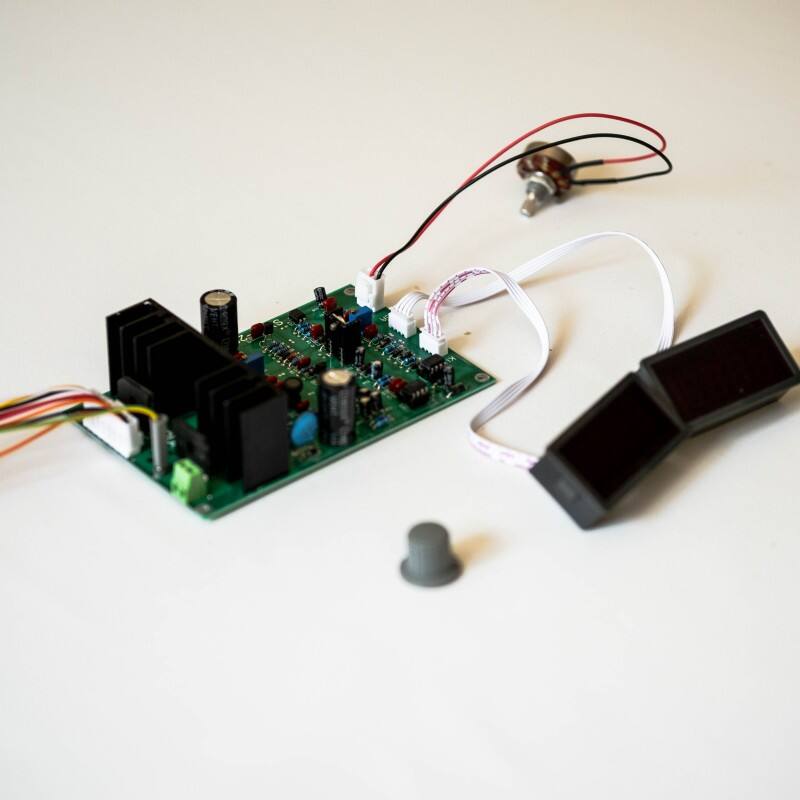

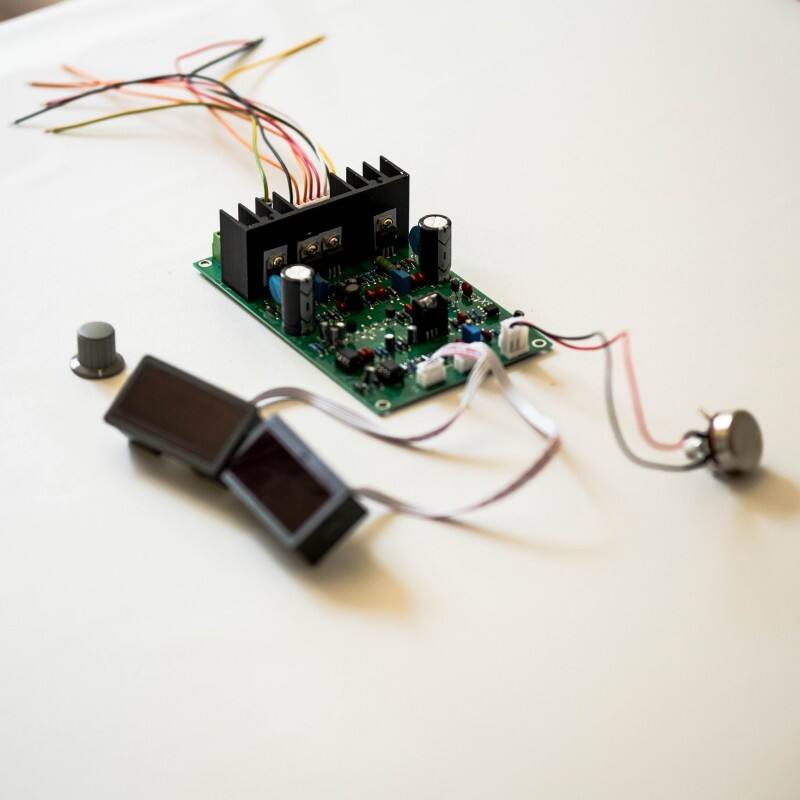

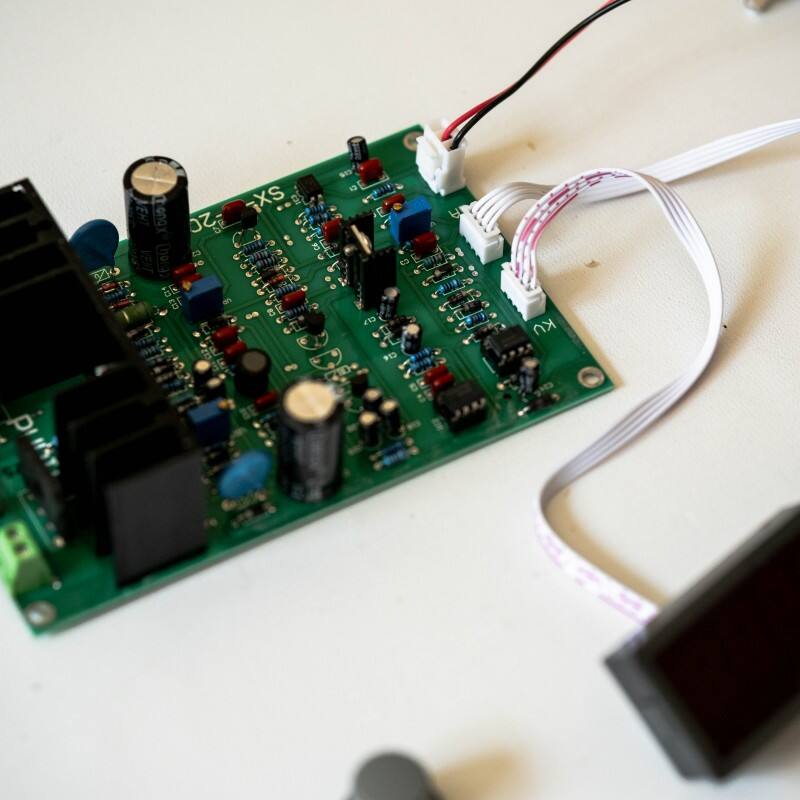

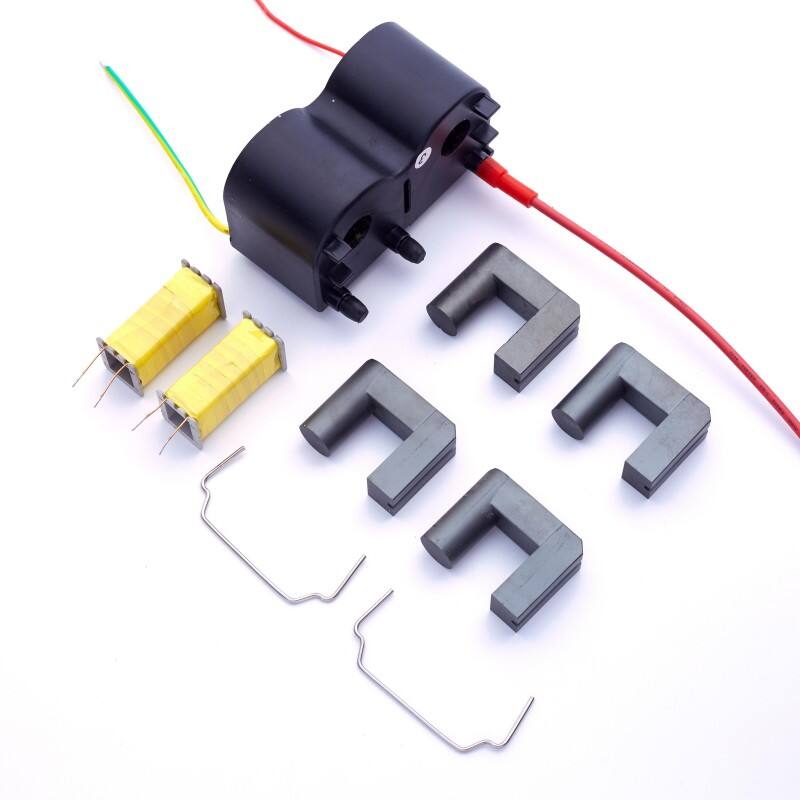

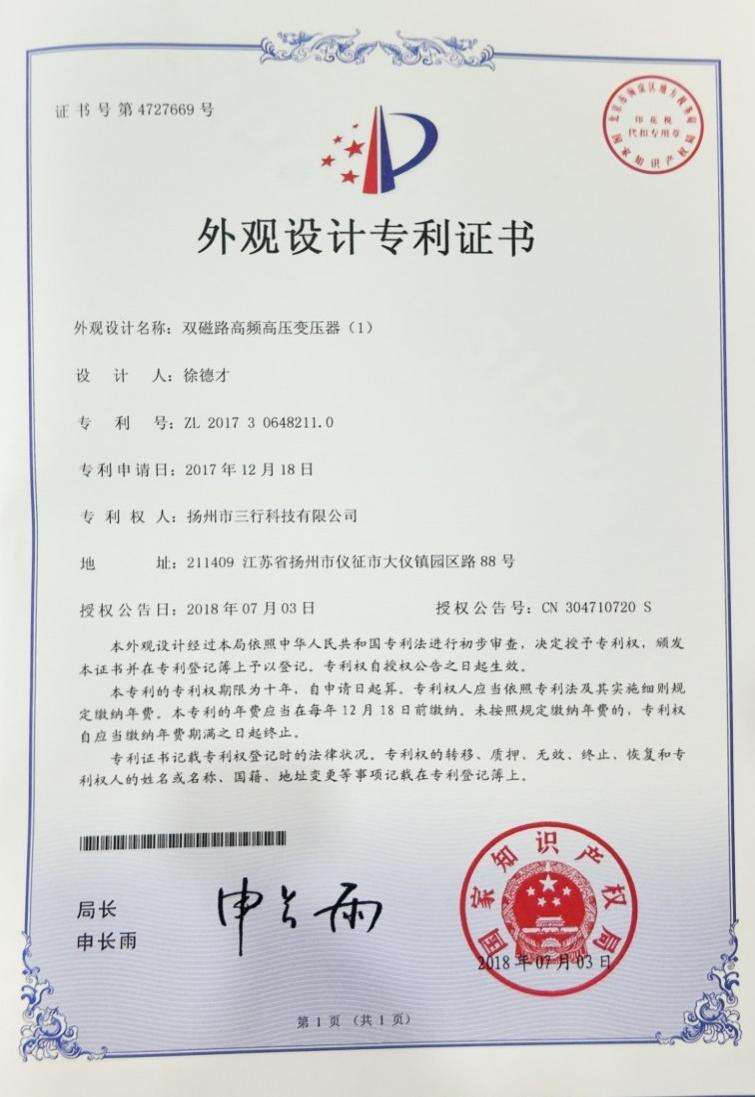

High-Voltage Module For Electrostatic Spraying SX-208

| Place of Origin | China |

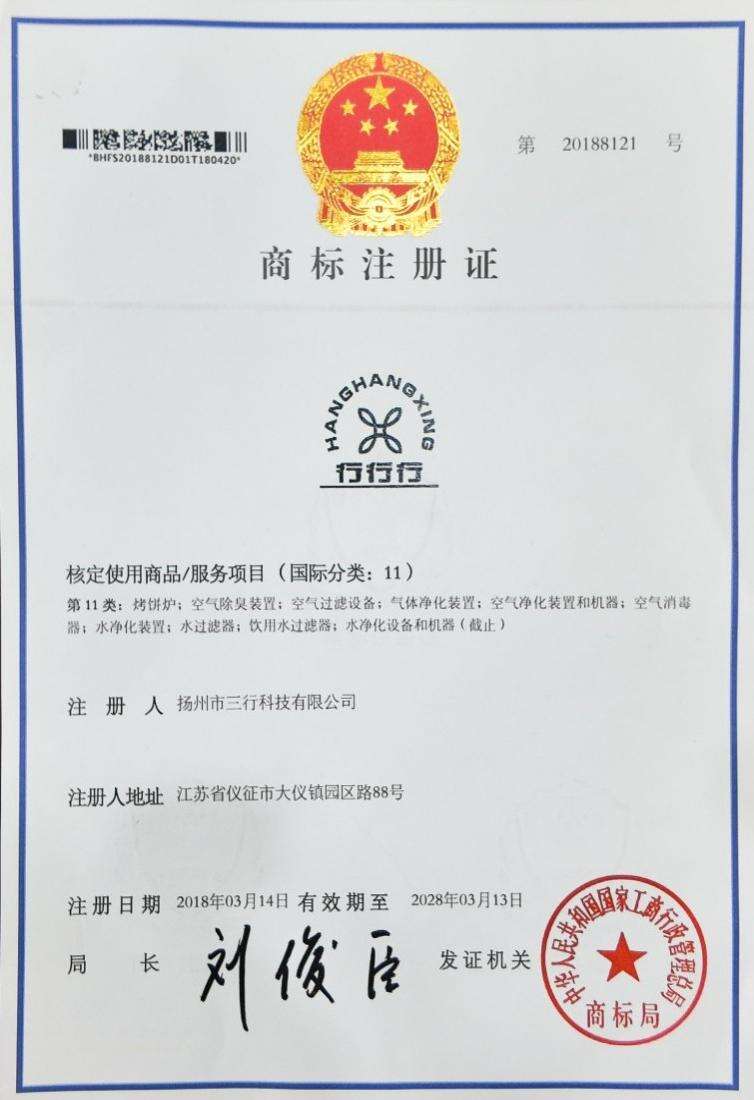

| Brand Name | Hanghangxing |

| Certification | CE |

- Overview

- Recommended Products

Description

In the precision-driven industry of industrial coating and electrostatic spraying, the performance of your system depends on the reliability and efficiency of its high-voltage module. We are proud to present our groundbreaking Built-in High-Voltage Module—an engineering pinnacle designed to redefine stability, compatibility, and cost-effectiveness in your operations. This is not merely an ordinary component; it is the strategic upgrade your equipment deserves.

1. Uncompromising Durability: A Casing Engineered to Withstand Extreme Conditions

The integrity of any critical component begins with its primary defense: the outer casing. Our module is fitted with a specially formulated composite material that establishes a new benchmark for durability in harsh industrial environments.

• Exceptional Heat Resistance: Unlike standard plastics that may warp or degrade, our composite shell retains structural integrity during continuous high-load operations. It effectively dissipates heat, preventing internal component failure and ensuring consistent performance even in the demanding, high-temperature conditions of spray gun assemblies.

• Superior High-Pressure Tolerance: The material boasts an excellent strength-to-weight ratio, offering remarkable resistance to physical stress and high-pressure environments. This robust construction eliminates the risk of casing cracks or microfractures, which can lead to catastrophic failure and dangerous arc-overs.

• Guaranteed Long-Term Stability: The synergy between advanced material science and precision manufacturing produces a module highly resistant to chemical corrosion, moisture, and impact. This translates to exceptional long-term stability, minimizing downtime and maximizing your return on investment by supplying a reliable power source day in and day out.

2. Unparalleled Adaptability: Seamless Integration and Customized Solutions

We understand that a one-size-fits-all approach does not work for modern manufacturing. Our high-voltage module is engineered from scratch to provide maximum flexibility and ease of integration.

• Broad Compatibility: Our standard modules are designed to be compatible with a wide range of electrostatic spraying systems and spray gun models from different manufacturers. Whether you use mainstream European brands or versatile Asian models, our product is likely to integrate seamlessly, reducing retrofitting complexity and costs.

• Tailored to Your Specifications: Beyond standard compatibility, we offer bespoke customization services. By providing your host equipment’s specific parameters—including voltage/current requirements, communication protocols, and physical dimensions—our engineering team can tailor a module that perfectly fits your system. This ensures optimal performance, preserves your equipment’s warranty, and extends the lifecycle of your entire coating setup.

3. Superior Cost-Effectiveness: Strategic Savings Without Sacrificing Performance

In today’s competitive business landscape, managing operational costs is crucial. Our product delivers world-class performance at a fraction of the cost of comparable high-end modules, presenting an irresistible value proposition.

• Direct Cost Savings: When compared to equivalent high-end modules from European and American manufacturers, our product comes with a significantly lower initial investment. This immediate cost reduction directly cuts your capital expenditure (CapEx) and spare parts inventory costs.

• Practical and Reliable Design: We focus on the essentials for field use: robust performance and operational simplicity. While some premium-priced competitors add complex features that are rarely utilized, we concentrate on delivering unshakable stability and practical functionality. This means you pay for real value, not superfluous extras.

• Reduced Total Cost of Ownership (TCO): Our competitive pricing, exceptional durability, and low failure rate combine to deliver a dramatically reduced Total Cost of Ownership. By minimizing unplanned downtime, maintenance intervals, and replacement frequency, our module actively helps you lower operational expenditures (OpEx) over its entire service life. You achieve substantial cost savings without any compromise on the stability and quality of your electrostatic spraying process.

Conclusion

Our Built-in High-Voltage Module is more than a component—it is a strategic partner for your business growth. It embodies a perfect balance of rugged reliability, flexible application, and outstanding economic value.

Ready to boost your coating system’s performance and profitability? Contact our technical sales team today for a personalized consultation and find out how our module can be tailored to meet your specific requirements.

Product specification

| Place of Origin | China |

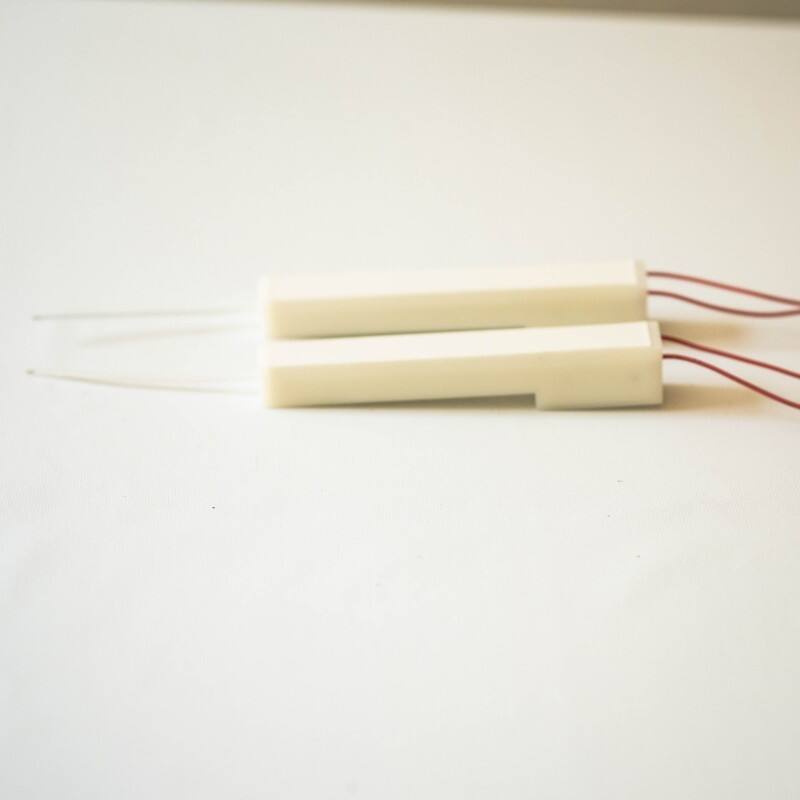

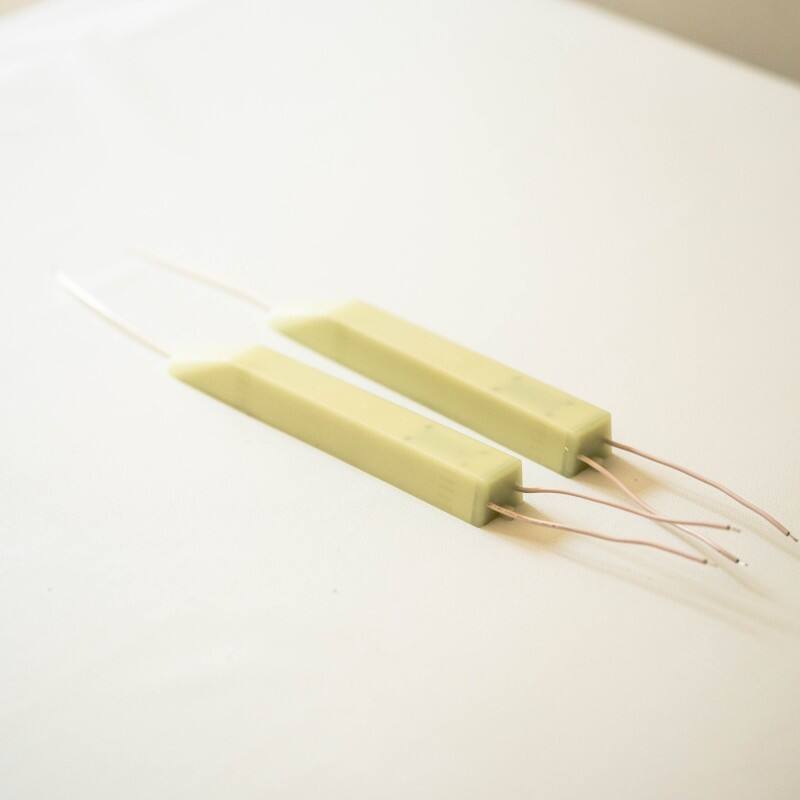

| Size of product | 190*30*20mm |

| Weight | 175g |

| Output Voltage | 12V/15V/18V/24V |

Applications

1. Uniform coloring of details on precision handicrafts

2. Product painting on industrial assembly lines – significantly enhances work efficiency and reduces labor costs

In the challenging field of electrostatic coating, mastering both intricate artistry and large-scale industrial production requires a core component that delivers uncompromising performance. Our built-in high-voltage module is specifically engineered to meet this dual demand, setting a new standard for efficiency and reliability across diverse application scenarios.

1. Unmatched Precision for Complex and Delicate Parts

An electrostatic system’s true strength lies in its ability to handle complex geometries with tricky recesses and dead angles – and our module stands out in this exact area. It provides a decisive advantage for coating precision crafts, automotive accessories, electronic housings, and other intricate components.

• Superior Transfer Efficiency and Uniformity: Our technology’s core enables an exceptionally high powder deposition rate (transfer efficiency), achieved through the module’s generation of a perfectly stabilized and optimized electrostatic field. The result is a much more uniform and consistent cloud of charged powder particles.

• Conquering Faraday Cage Areas: The "Faraday cage" effect – where powder is repelled from recessed areas and edges, leading to inconsistent film build and poor coverage – is a common struggle for traditional coating methods. Our module’s advanced field control ensures active and even powder attraction into these hard-to-reach cavities and sharp edges. This capability drastically reduces the need for manual rework, minimizes material waste, and guarantees a flawless, first-time-right finish on even the most complex workpiece geometries.

2. Robust Reliability for Demanding Industrial Environments

Precision is essential for delicate parts, but relentless durability is a must for high-volume industrial manufacturing. Our built-in high-voltage module is designed to withstand the harsh conditions of continuous operation on automated production lines for appliances, furniture, and architectural components.

• Engineered for Continuous Uptime: For large-scale automated assembly lines, unplanned downtime means substantial financial loss. Our modules are constructed with industrial-grade components and equipped with advanced protection circuits against overloads, voltage spikes, and temperature fluctuations. This robust design ensures stable output and consistent performance over long periods, shift after shift.

• Consistent Quality in High-Throughput Settings: In applications such as metal furniture or aluminum profile coating, maintaining a uniform finish across thousands of parts is critical. Our module’s exceptional stability ensures that the electrostatic charge applied to each individual part remains constant. This eliminates batch-to-batch variations, ensures color consistency, and delivers a high-quality finish on every product from the automated line, boosting your brand’s reputation for quality.

Conclusion

Whether it’s the finest detail on a precision craft or the relentless pace of high-volume automated assembly lines, our built-in high-voltage module is the critical bridge between application challenges and coating perfection. It is the intelligent, reliable choice for businesses that refuse to compromise between exquisite detail and industrial ruggedness.

Upgrade your coating process with technology that offers both finesse and force. Contact us to find the ideal high-voltage solution for your specific application.

FAQ

Q: How long does production and delivery take?

A: The production cycle for standard parameters typically ranges from 4 to 5 days, while customized products may take up to 10 days. Generally, the logistics time for international shipments is between one and two weeks.

Q: Can I request custom designs or sizes?

A: Certainly. We can manufacture products according to the parameters you provide. Regarding the dimensions, we will definitely meet your requirements to the best of our ability. If the subsequent order volume is substantial, we can offer the service of creating a dedicated mold for your specified products at our own expense.

Q: What is the fastest way to contact you?

A: WeChat APP is the fastest way to contact me,my ID is ppxs0712,and you can also send me email, I will check it everyday. My WhatsApp / phone number is +8618168269966, and my email is [email protected].

Q:What are your shipping terms?

A:Normally, the volume of our goods is not very large. For international shipments, we do not cover the shipping costs. Usually, the shipping fees are calculated based on the weight and volume of the products. According to our past experience, the shipping costs will not be very high.