Ozone technology has emerged as a revolutionary solution in industrial cleaning and purification applications across diverse sectors. This powerful oxidizing agent offers unparalleled effectiveness in eliminating contaminants, pathogens, and pollutants while maintaining environmental sustainability. Industries worldwide are increasingly adopting ozone technology to enhance their cleaning protocols, reduce chemical dependencies, and achieve superior purification results that traditional methods cannot match.

The implementation of ozone technology in industrial settings represents a paradigm shift from conventional cleaning methodologies. Unlike chemical-based cleaning systems that often leave residues and require extensive rinsing, ozone technology provides a clean, residue-free solution that naturally decomposes back into oxygen. This characteristic makes ozone technology particularly valuable in industries where contamination control is critical, such as food processing, pharmaceutical manufacturing, and semiconductor production.

Manufacturing facilities utilizing ozone technology experience significant improvements in operational efficiency and product quality. The technology's ability to penetrate surfaces and reach areas that traditional cleaning methods cannot access ensures comprehensive purification throughout industrial systems. Furthermore, ozone technology eliminates the need for storing and handling hazardous chemicals, reducing workplace safety risks and regulatory compliance burdens for industrial operators.

Fundamental Principles of Industrial Ozone Technology

Molecular Structure and Oxidation Mechanisms

Ozone technology operates through a sophisticated oxidation process that fundamentally alters the molecular structure of contaminants. The ozone molecule consists of three oxygen atoms, creating an unstable configuration that readily releases its third oxygen atom to react with organic and inorganic pollutants. This oxidation mechanism enables ozone technology to break down complex molecular chains of bacteria, viruses, fungi, and chemical compounds into harmless byproducts.

The oxidation potential of ozone technology exceeds that of chlorine by approximately 50%, making it one of the most potent oxidizing agents available for industrial applications. This superior oxidizing power allows ozone technology to neutralize resistant microorganisms and persistent organic pollutants that conventional disinfectants cannot effectively eliminate. The rapid reaction kinetics of ozone technology ensure quick decontamination cycles, minimizing downtime in industrial processes.

Generation Methods and System Integration

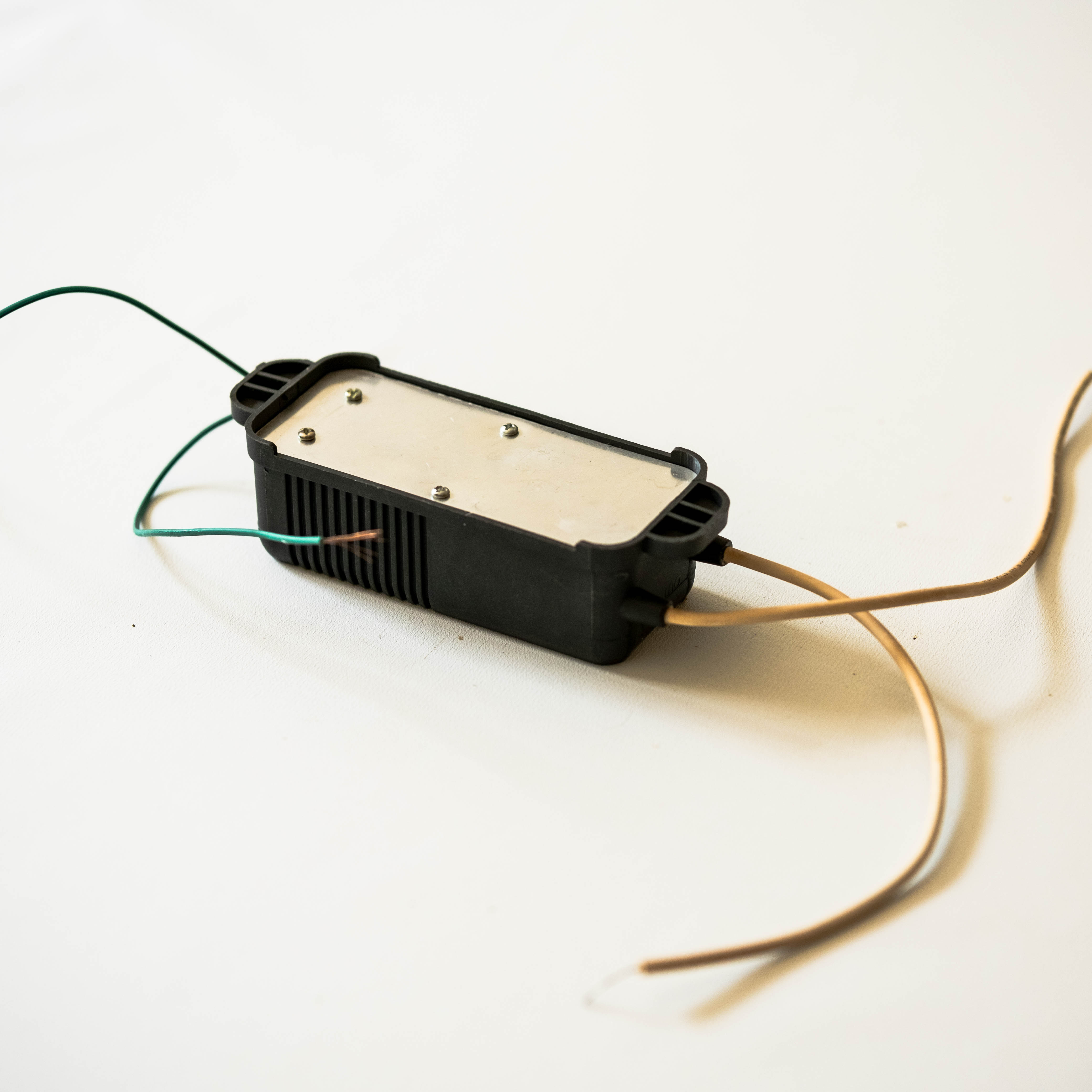

Industrial ozone technology systems employ various generation methods to produce ozone on-site for immediate application. Corona discharge generators represent the most common approach, utilizing high-voltage electrical fields to split oxygen molecules and recombine them into ozone. This method allows for precise control over ozone concentrations, enabling operators to optimize ozone technology performance for specific cleaning and purification requirements.

UV ozone generators offer an alternative approach for smaller-scale applications, utilizing ultraviolet light at 185 nanometers to produce ozone from ambient air. These systems integrate seamlessly into existing industrial infrastructure, providing flexibility in ozone technology deployment. Advanced control systems monitor ozone concentrations, contact time, and environmental conditions to ensure optimal performance and safety compliance throughout industrial operations.

Applications Across Industrial Sectors

Food and Beverage Processing

The food and beverage industry has extensively adopted ozone technology for sanitizing processing equipment, storage containers, and production environments. Ozone technology effectively eliminates pathogenic microorganisms including Salmonella, E. coli, and Listeria without leaving chemical residues that could affect product taste or safety. Food processors utilize ozone technology for washing fruits and vegetables, extending shelf life while maintaining nutritional value and organoleptic properties.

Beverage manufacturers implement ozone technology for bottle sterilization, water treatment, and equipment cleaning between production runs. The technology's ability to penetrate biofilms and eliminate spoilage organisms ensures product consistency and safety throughout the production chain. Ozone technology also provides effective odor control in food processing facilities, maintaining pleasant working environments while meeting stringent hygiene standards.

Pharmaceutical and Biotechnology Manufacturing

Pharmaceutical facilities require the highest levels of cleanliness and contamination control, making ozone technology an ideal solution for these demanding applications. The technology's broad-spectrum antimicrobial activity eliminates bacteria, viruses, spores, and fungi that could compromise product integrity or patient safety. Ozone technology effectively sanitizes cleanrooms, manufacturing equipment, and HVAC systems without introducing foreign substances that could interfere with pharmaceutical formulations.

Biotechnology companies utilize ozone technology for sterilizing fermentation vessels, bioreactors, and downstream processing equipment. The technology's compatibility with stainless steel and other pharmaceutical-grade materials ensures equipment longevity while maintaining validation requirements. Ozone technology also provides effective decontamination of waste streams, ensuring environmental compliance and protecting public health.

Operational Advantages and Performance Benefits

Environmental Sustainability and Safety

Ozone technology offers significant environmental advantages compared to traditional chemical cleaning systems. The technology produces no harmful byproducts or persistent residues, as ozone naturally decomposes into oxygen within minutes of application. This characteristic eliminates the need for waste treatment systems and reduces environmental impact throughout industrial operations. Ozone technology also eliminates the transportation, storage, and disposal challenges associated with hazardous cleaning chemicals.

Worker safety improves dramatically with ozone technology implementation, as operators no longer handle corrosive or toxic cleaning agents. Proper ventilation and monitoring systems ensure safe ozone levels during operation, while automated controls minimize human exposure. The elimination of chemical mixing, dilution, and handling procedures reduces accident risks and workers' compensation claims for industrial facilities utilizing ozone technology.

Cost Effectiveness and Operational Efficiency

Industrial facilities implementing ozone technology experience substantial cost savings through reduced chemical purchases, storage requirements, and waste disposal expenses. The on-site generation capability of ozone technology eliminates supply chain dependencies and price volatility associated with chemical cleaning agents. Labor costs decrease significantly as ozone technology requires minimal operator intervention compared to complex chemical mixing and application procedures.

Energy efficiency represents another significant advantage of ozone technology, as modern generators consume minimal electricity while producing high concentrations of active ozone. The rapid action of ozone technology reduces contact times and water usage compared to traditional cleaning methods. These operational efficiencies translate into improved productivity and profitability for industrial facilities adopting ozone technology solutions.

Implementation Strategies and Best Practices

System Design and Installation Considerations

Successful implementation of ozone technology requires careful consideration of system design parameters including ozone generation capacity, distribution methods, and monitoring systems. Engineers must evaluate facility layout, ventilation requirements, and process integration points to optimize ozone technology performance. Proper sizing ensures adequate ozone concentrations while avoiding over-treatment that could damage sensitive materials or increase operating costs.

Installation procedures for ozone technology systems must comply with relevant safety codes and industry standards. Electrical systems require proper grounding and surge protection to ensure reliable ozone generator operation. Piping materials must be compatible with ozone exposure, typically requiring stainless steel or ozone-resistant polymers. Ventilation systems must provide adequate air changes to maintain safe working environments during ozone technology operation.

Monitoring and Maintenance Protocols

Effective monitoring systems ensure optimal ozone technology performance while maintaining safety compliance throughout industrial operations. Real-time ozone concentration monitors provide continuous feedback on system performance and environmental conditions. Data logging capabilities enable trend analysis and predictive maintenance scheduling to maximize ozone technology reliability and minimize unexpected downtime.

Preventive maintenance programs for ozone technology systems include regular cleaning of generator electrodes, replacement of consumable components, and calibration of monitoring instruments. Operator training ensures proper system operation and emergency response procedures. Documentation systems track maintenance activities, performance metrics, and regulatory compliance for ozone technology installations throughout their operational lifecycle.

Emerging Technologies and Future Applications

Advanced Ozone Generation Systems

Recent developments in ozone technology include advanced power supplies that improve energy efficiency and ozone production rates. Pulsed power systems optimize electrical energy delivery to corona discharge reactors, increasing ozone yield while reducing power consumption. These innovations make ozone technology more cost-effective for large-scale industrial applications requiring high ozone concentrations and continuous operation.

Plasma-based ozone generators represent another technological advancement, utilizing atmospheric pressure plasma to produce ozone with improved stability and concentration control. These systems offer enhanced reliability and reduced maintenance requirements compared to traditional corona discharge generators. Integration with smart control systems enables remote monitoring and optimization of ozone technology performance across multiple industrial facilities.

Integration with Industry 4.0 Technologies

The integration of ozone technology with Internet of Things sensors and artificial intelligence systems creates opportunities for predictive maintenance and automated optimization. Machine learning algorithms analyze operating data to identify patterns and recommend adjustments for improved ozone technology performance. These smart systems can automatically adjust ozone concentrations based on contamination levels, environmental conditions, and production schedules.

Digital twin technologies enable virtual modeling of ozone technology systems, allowing engineers to optimize designs and predict performance before installation. These capabilities reduce implementation risks and accelerate deployment timelines for new ozone technology applications. Cloud-based monitoring platforms provide centralized oversight of multiple ozone technology installations, enabling enterprise-wide optimization and compliance management.

FAQ

What makes ozone technology more effective than traditional chemical disinfectants

Ozone technology provides superior antimicrobial effectiveness due to its powerful oxidation potential, which is approximately 1.5 times stronger than chlorine. Unlike chemical disinfectants that may leave residues or lose effectiveness over time, ozone technology acts immediately upon contact and decomposes naturally into oxygen, leaving no harmful byproducts. This makes ozone technology particularly valuable for industries requiring residue-free cleaning and sterilization.

How does ozone technology impact operational costs compared to conventional cleaning methods

Ozone technology significantly reduces operational costs by eliminating the need for purchasing, storing, and disposing of chemical cleaning agents. On-site ozone generation eliminates supply chain costs and price volatility associated with chemical purchases. Additionally, ozone technology reduces water usage, labor requirements, and waste treatment expenses, resulting in substantial long-term cost savings for industrial facilities.

What safety considerations are important when implementing ozone technology in industrial settings

Proper implementation of ozone technology requires adequate ventilation systems to maintain safe air quality levels during operation. Continuous ozone monitoring systems provide real-time concentration readings and automated safety shutoffs when levels exceed permissible limits. Worker training programs ensure proper operating procedures and emergency response protocols. When properly designed and operated, ozone technology provides a safer alternative to handling hazardous chemical cleaning agents.

Can ozone technology be integrated with existing industrial cleaning systems

Ozone technology systems are designed for seamless integration with existing industrial infrastructure through flexible installation options and standardized connection interfaces. Retrofit capabilities allow facilities to upgrade their cleaning processes without extensive modifications to existing equipment. Control systems can interface with facility automation networks to coordinate ozone technology operation with production schedules and other industrial processes, ensuring optimal efficiency and minimal disruption to operations.

Table of Contents

- Fundamental Principles of Industrial Ozone Technology

- Applications Across Industrial Sectors

- Operational Advantages and Performance Benefits

- Implementation Strategies and Best Practices

- Emerging Technologies and Future Applications

-

FAQ

- What makes ozone technology more effective than traditional chemical disinfectants

- How does ozone technology impact operational costs compared to conventional cleaning methods

- What safety considerations are important when implementing ozone technology in industrial settings

- Can ozone technology be integrated with existing industrial cleaning systems